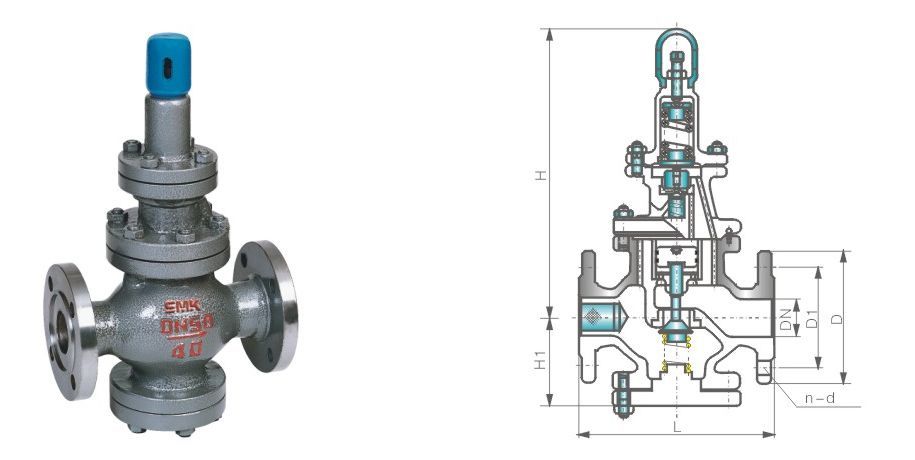

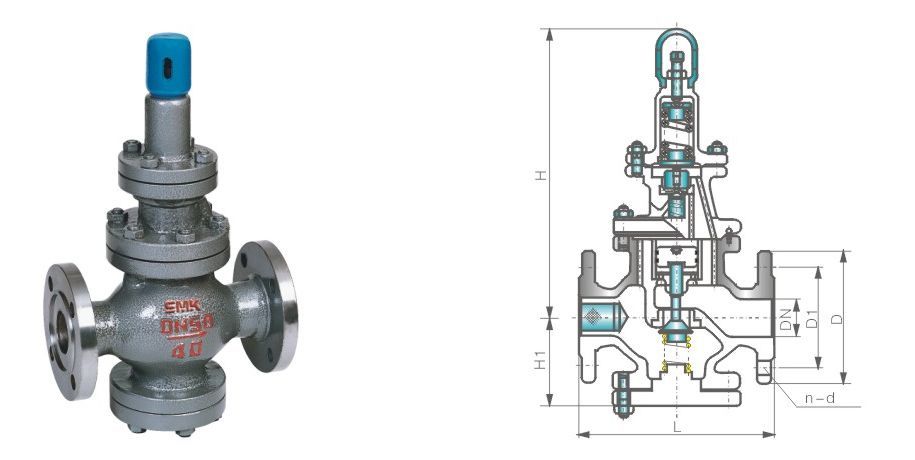

Y43W/H蒸汽減壓閥

產(chǎn)品概述/Product outline

Y43W/H系列蒸汽減壓閥適用于蒸汽管路上。通過減壓閥的調(diào)節(jié),可使進(jìn)口壓力降至某一需要的出口壓力,當(dāng)進(jìn)口壓力或流量變動(dòng)時(shí),減壓閥依靠介質(zhì)本 身的能量,使閥后壓力自動(dòng)滿足預(yù)定值,從而適應(yīng)工況的要求。

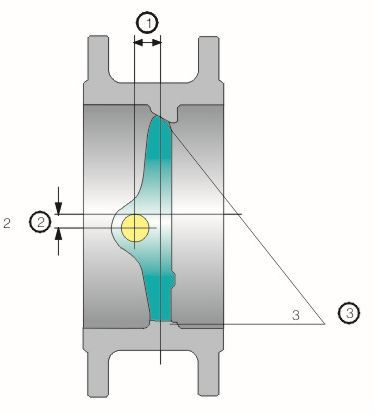

主要零部件材料/Main spare part material

| 零件名稱 Components name |

材料 Material |

| 閥體、上蓋、下蓋、帽蓋 Valve chest, top head, under lid, capping |

球墨鑄鐵、鑄鋼 Modular cast iron, cast steel |

| 主導(dǎo)盤、主閥座、導(dǎo)閥盤、導(dǎo)閥座 The main godet, the host valve seat, lead the valve disk, to lead the valve seat |

不銹鋼 Stainless steel |

| 彈簧Spring |

鉻釩鋼、硅錳鋼 Chromium vanadium steel, silicon-manganese steel |

| 活塞Piston |

銅合金、不銹鋼 Copper alloy, stainless steel |

技術(shù)參數(shù)/Technical parameter

| 公稱壓力 Nominal pressure (Mpa) |

1.6 |

2.5 |

4.0 |

6.4 |

| 試驗(yàn)壓力 Test pressure (MPa) |

殼體Shell |

2.4 |

3.75 |

6.0 |

9.6 |

| 密封Seal |

1.76 |

2.75 |

4.4 |

7.04 |

| 進(jìn)口壓力Inlet pressure |

≤1.6 |

≤2.5 |

≤4.0 |

≤6.4 |

| 出 口壓力Outlet pressure |

0.05-1.1 |

0.1-1.6 |

0.1-2.5 |

0.5-3.5 |

| 適用溫度uitable the temperature(℃) |

≤300 |

≤350 |

≤400 |

≤425 |

| 適用介質(zhì)suitable the medium |

蒸汽 Steaming Steam |

主要連接外型尺寸/Main connection outlook size 單位:mm

| DN |

L |

H |

H1 |

1.6MPa |

2.5MPa |

4.0MPa |

6.4MPa |

| D |

D1 |

n-d |

D |

D1 |

n-d |

D |

D1 |

n-d |

D |

D1 |

n-d |

| 15 |

160/160 |

280 |

85 |

95 |

65 |

4-14 |

95 |

65 |

4-14 |

95 |

65 |

4-14 |

105 |

75 |

4-14 |

| 20 |

160/180 |

295 |

85 |

105 |

75 |

4-14 |

105 |

75 |

4-14 |

105 |

75 |

4-14 |

125 |

90 |

4-18 |

| 250 |

180/200 |

295 |

100 |

115 |

85 |

4-14 |

115 |

85 |

4-14 |

115 |

85 |

4-14 |

135 |

100 |

4-18 |

| 32 |

200/220 |

295 |

100 |

135 |

100 |

4-18 |

135 |

100 |

4-18 |

135 |

100 |

4-18 |

150 |

110 |

4-23 |

| 40 |

220/240 |

310 |

105 |

145 |

110 |

4-18 |

145 |

110 |

4-18 |

145 |

110 |

4-18 |

165 |

125 |

4-23 |

| 50 |

250/270 |

310 |

105 |

160 |

125 |

4-18 |

160 |

125 |

4-18 |

160 |

125 |

4-18 |

175 |

135 |

4-23 |

| 65 |

280/300 |

310 |

105 |

180 |

145 |

8-18 |

180 |

145 |

8-18 |

180 |

145 |

8-18 |

200 |

160 |

8-23 |

| 80 |

310/330 |

355 |

160 |

195 |

160 |

8-18 |

195 |

160 |

8-18 |

195 |

160 |

8-18 |

210 |

170 |

8-23 |

| 100 |

350/380 |

355 |

160 |

215 |

180 |

8-18 |

320 |

190 |

8-23 |

230 |

190 |

8-23 |

250 |

200 |

8-25 |

| 125 |

400/450 |

390 |

200 |

245 |

210 |

8-18 |

270 |

220 |

8-25 |

270 |

220 |

8-25 |

295 |

24 |

8-30 |

| 150 |

450/500 |

390 |

200 |

280 |

240 |

8-23 |

300 |

250 |

8-25 |

300 |

250 |

8-25 |

340 |

280 |

8-34 |

| 200 |

500/550 |

440 |

260 |

335 |

295 |

12-23 |

360 |

310 |

12-25 |

360 |

320 |

12-30 |

405 |

345 |

12-34 |

| 250 |

650 |

490 |

280 |

405 |

355 |

12-25 |

425 |

370 |

12-30 |

425 |

285 |

12-34 |

470 |

400 |

12-41 |

| 300 |

800 |

545 |

320 |

480 |

410 |

12-25 |

485 |

430 |

16-30 |

485 |

450 |

16-34 |

530 |

460 |

16-41 |

| 350 |

900 |

590 |

355 |

520 |

470 |

16-25 |

550 |

490 |

16-34 |

550 |

510 |

16-34 |

585 |

525 |

16-41 |

| 400 |

1000 |

635 |

390 |

580 |

525 |

16-30 |

610 |

550 |

16-34 |

610 |

585 |

16-41 |

670 |

585 |

16-48 |